- +44 (0) 1663 736260

- info@website.com

- Mon - Fri: 9:00 - 18:30

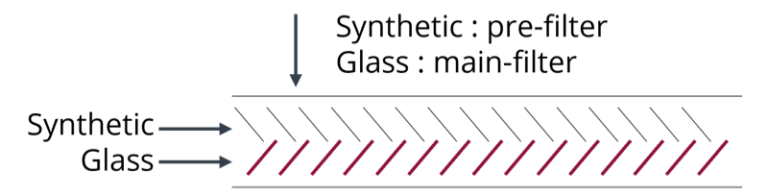

HEPA media are typically used at low face velocities in the range of 2 – 2,5 cm/s. However, in some application higher flow rates are required due to lack of installation space. Besides higher pressure drop, a higher filtration velocity will also reduce the filter efficiency and thus lowers the filter class. The new BinNova data sheets clearly show the filter class at different (and also high) face velocities so that each customer can choose the right material according to the final application (real-life conditions).

The implementation of ISO 16890 looks to better protect human health, through more effective methods of filter media evaluation. The new standard evaluates filter media based on a multi-tier system that is designed to meet recommendations set by the World Health Organization (WHO). This will take into account the size of pollutants, as well as whether or not they are likely to penetrate into the human body and pose any health risks. By distinguishing between PM 10 (< 10 μm), PM 2.5 (< 2.5 μm) and PM 1 (< 1 μm) particles, ISO 16890 aims to provide an increased level of safety and security for users by ensuring greater levels of air quality control.

It is becoming increasingly evident that the evaluation of filter media needs to evolve in order to tackle new industry standards, such as ISO 16890. BinNova took on this challenge head-on and adjusted their filter grades and accompanying data sheets. Such a shift can often require an entire rethink of the way filter media has been classed and used up until this point – but BinNova are leading the charge in this area, proving that they are capable of adapting to meet customer needs in a continuously changing market.

Adding a HEPA filter to an existing ventilation system comes with its challenges, especially when it involves space constraints. Without sufficient installation space, increasing the face velocities of the media can be necessary to meet performance demands. Unfortunately, this also induces a pressure drop and significantly reduces the filter efficiency of HEPA media, thus lowering the classification grade. To alleviate this issue and ensure customers receive the best product for their application conditions, BinNova has revealed data sheets that demonstrate how different filtering velocities effect the grade of their products. By doing this, customers are provided with comprehensive information and given the power to make informed decisions about choosing the best material for their ventilation needs.